- #FLUKE NETWORK INSPECTOR KEY CRACKED#

- #FLUKE NETWORK INSPECTOR KEY PATCH#

- #FLUKE NETWORK INSPECTOR KEY PORTABLE#

- #FLUKE NETWORK INSPECTOR KEY PRO#

#FLUKE NETWORK INSPECTOR KEY PATCH#

Simply insert the fiber inspection probe and inspect installed fiber connectors through the bulkhead adapters without accessing the backside of the patch panels. Using a fiber optic inspection video microscope also completely ensures that no harmful laser light ever reaches your eyes.

#FLUKE NETWORK INSPECTOR KEY PORTABLE#

Its miniature size makes the FiberInspector Mini fiber inspection scope extremely portable and convenient. The fiber inspection device displays exceptionally sharp images on its 1.8” screen. Extend battery life in the grip trigger mode, when the device only shows images when squeezing the sides of the display.

With a range of standard and accessory inspection probe tips, end-faces can be inspected when using many different connector types, including LC connectors. When damage is observed upon inspecting an end-face, it must be determined what needs to be done, if anything. Some damage may be minor enough to ignore while other problems require complete re-termination. Solution: Visually determine if chips are within acceptable limits, up to 5% of the outside edge of the fiber cladding generally may be chipped, as this is a common result of the polishing process. Any chips on the fiber core are not acceptable. If chips are beyond acceptable limits, the fiber should be re-terminated. Scratched and epoxy bleed fiber end-face? Solution: If the end-face is scratched, has polishing debris or has excess epoxy bleed, then repolish it with fine lapping paper until visual inspection shows scratches and debris gone.

#FLUKE NETWORK INSPECTOR KEY CRACKED#

Solution: If the end-face is cracked or shattered, then re-terminate the fiber.

Cracks can spread, making the end-face unacceptable. Once contamination has been discovered using a fiber microscope, it is crucial that it be properly removed to avoid creating more problems. Proper cleaning products and procedures are a requirement as improper processes are not only ineffective, but also potentially damaging.Įffective fiber optic end-face cleaning involves two key components: specialized solvent and wipes or swabs. Fiber optic solvent is required to dissolve certain contaminants and to act as a lubricant so that debris does not scratch the end-face as it is removed. Do not use isopropyl alcohol (IPA) as this chemical can leave a residue as it dries. Kits offered by Fluke Networks contain everything needed for precision cleaning of end-faces on connectors and inside ports.Īfter cleaning, always inspect the end-face again before insertion to guarantee all contaminants were removed.

Setting a reference for a simplex link.If necessary, repeat your cleaning steps to remove any lingering soils not removed by the first cycle.įluke Networks’ fiber microscopes will allow you to avoid the most common problem with fiber networks. Understanding how the different connector losses differ from other standards. Setting a reference for a duplex link, LC to LC duplex. Configuring the CertiFiber Pro, Fiber inspection, Automated analysis.

#FLUKE NETWORK INSPECTOR KEY PRO#

CertiFiber™ Pro testing, Basic fiber theory, Encircled flux.

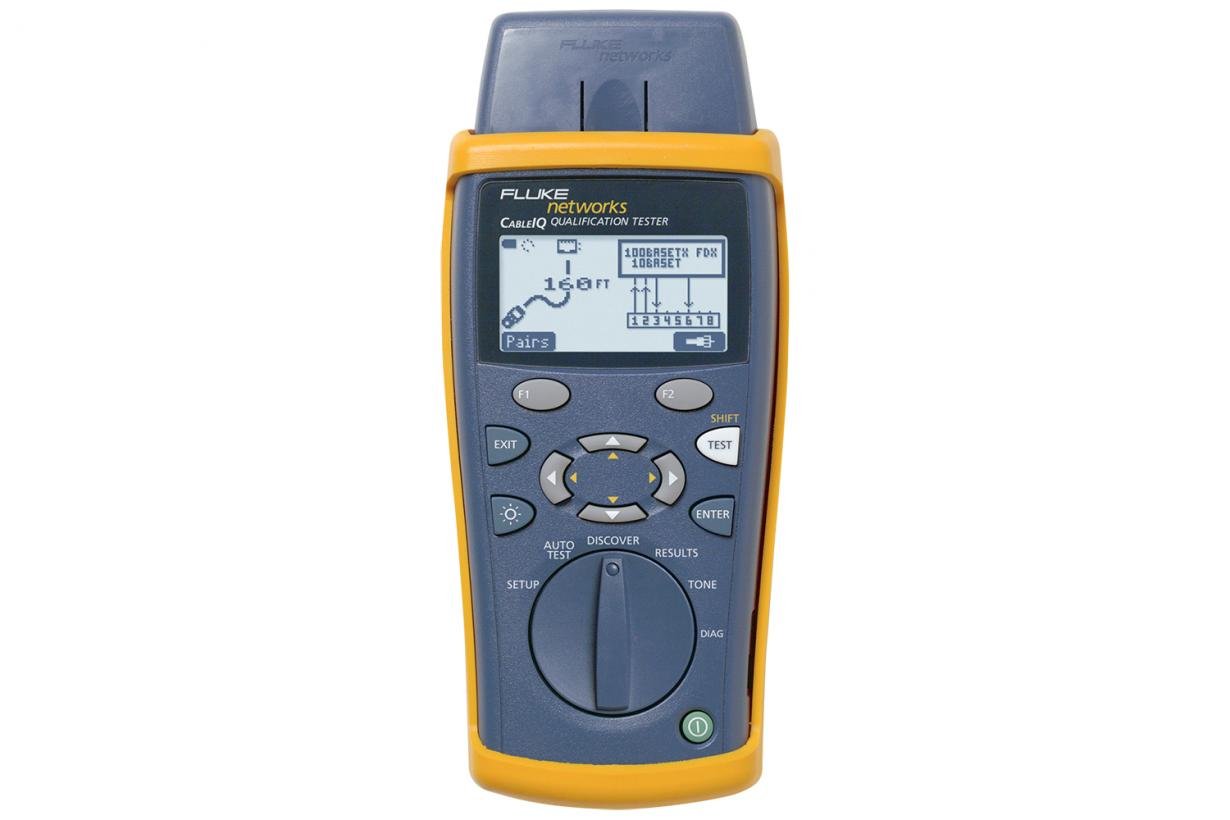

New test parameters: DC Resistance Unbalance, TCL, ELTCTL. DSX Series CableAnalyzer™ testing, Versiv™ introduction and common settings, Exporting configuration and results, Copper test limits/standards, Adapter types, Configuring for a twisted pair test, Making a measurement and reviewing the result. The Fluke Networks Certified Cabling Test Technician™ (CCTT) course consists of two days, each comprised of three parts - classroom training, hands-on labs, and exam/certification exercises.ĭay One – Copper. Fluke CCTT Training in Egypt is presented and empowered by ITEVENTS.

0 kommentar(er)

0 kommentar(er)